As well known, nowadays picking they right windows it is crucial to to guarantee top thermal insulation to our house to keep the indoor climate as comfortable as possible in every season avoiding energy waste and losses. Thermal break windows mean windows with excellent thermal insulation performance: but are you sure you know the deepest meaning of “thermal break windows” and which features ensure top performances and an important save on bills?

Read more to take the right pick regarding your new windows.

Buying guide index on thermal break windows:

- What’s the meaning for thermal break windows?

- The thermal break and the interruption of thermal continuity

- How is the thermal break manufactured?

- Advantages and disadvantages of thermal break windows

- Which kind of windows can be “thermal break” windows and what are the benefits ?

- Thermal break windows and condensation

- Open joint windows

- A long-lasting comfy climate even in in cold or hot kind of climate with thermal break window

WHAT’S THE MEANING FOR THERMAL BREAK WINDOWS?

Thermal Break windows are named like this since they literally “cut” the hot flow which otherwise would occur between the inside and the outside of our house. Thanks to this “cut” made through a specific installing technic, which we’ll describe in a while, the hot flow between the two environments, indoor and outdoor, is interrupted and our house can keep a long-lasting comfy climate avoiding waste of money.

THE THERMAL BREAK AND THE PRINCIPLE OF THE INTERRUPTION OF CONTINUITY

During wintertime, when the temperature is colder, a heated building tends to disperse its heat to the outside, whereas in summer the warmer outside air penetrates inside. It is a physical law: a warm body tends to yield part of its heat to a colder body, creating what is called “thermal break”. This thermal break is precisely the cause of a waste of energy that on average in traditional buildings is 30%. This way eliminating or reducing the thermal break of the frames allows the improvement of the building insulation. Of course windows are not the only “weak point”: even well insulated walls and a roof are essential to ensure optimal insulation of our home.

HOW IS THERMAL BREAK MADE IN WINDOWS?

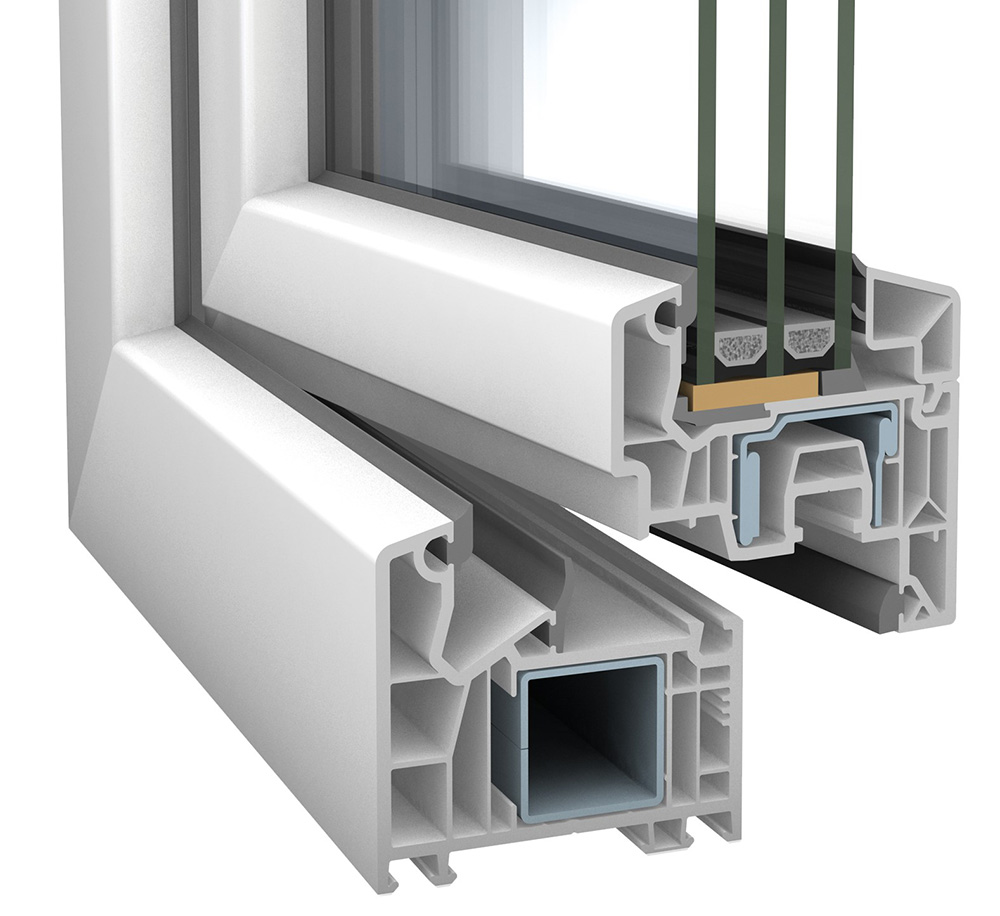

Thermal break windows are characterized by the insertion, in the central body, of an insulating material with low thermal conductivity inside the section, so that the two covers, the internal one and the external one, are separated and there is no thermal conductivity between them.

The insulating central body can be made in various materials, and this generally affects performance, increasing or decreasing the thermal transmittance index (a lower index means better performance) and influencing both the energy class and, of course, the price. In windows with higher performance the central body is in polyamide, in case of cheaper windows it is made of polystyrene.

It is therefore quite simple to check whether the windows of a building are thermal break ones or not: by opening the door you should see an element similar to plastic placed between the internal and external part of the window frame.

The thermal break technology was designed to solve the problem of the so-called “cold break” windows, the traditional ones, specifically the aluminum windows, which have a high thermal conductivity and therefore poor thermal insulation performance.

ADVANTAGES AND DISADVANTAGES OF THERMAL BREAK WINDOWS

As main pro:

- Higher thermal insulation

- Higher sound insulation

- energy saving

- less impact on the environment

- more comfort

The fundamental disadvantage is represented by the costs of thermal break windows compared to cold cut windows. However, the purchase costs mean energy savings that quickly make it possible to catch up on the initial investment. Furthermore, the replacement of traditional widows with thermal break ones that belong to an adequate energy class allows to benefit from tax deductions.

WHICH KIND OF WINDOWS CAN BE “THERMAL BREAK” AND WHAT ARE THE BENEFITS?

Historically, thermal breaking has been associated with aluminum windows, as it was created precisely to improve the performance of this type of fixtures. Aluminum in fact, unlike wood and PVC, is not able, by itself, to guarantee good insulation, since it is a material with high thermal conductivity.

The thermal break aluminum frames combine the natural durability and resistance of aluminum with the thermal insulation capacity of the thermal break. In terms of durability, resistance to oxidation and mechanical resistance, thermal break aluminum frames represent the best choice, combined with the wide range of colors available and the possibility of creating large bright and resistant windows.

The thermal break can also be combined with wooden windows, a material that is a natural excellent insulator. The wooden windows have a great aesthetic impact, but they need, as known, constant maintenance, a disadvantage that can however be mitigated if you choose aluminum windows with thermal break aluminum. The considerable weight of the wood also makes them less suitable than aluminum and PVC in case of large, oversized windows.

There is no mention of thermal break instead when it comes to PVC frames: PVC is in fact an excellent insulator and on average less expensive than aluminum or wooden windows with the same performance.

THERMAL BREAK WINDOWS AND CONDENSATION

While the old aluminum windows were easily subject to the phenomenon of condensation, the thermal break aluminum frames no longer have this annoying problem, thanks also to the insertion of a warm edge and argon gas between the two glass layers the internal and the external ones.

OPEN JOINT WINDOW

Another plus that further enhances the insulating performance of our window is the “open joint” technology. In fact, in some conditions the gaskets normally installed on the frames can detach themselves from the subframe due to the high external pressure, which can create a deformation of the door profile. The window is therefore no longer safe from water and air infiltration. With the open joint technique, a gasket is inserted inside the profile that is able to convey the water and the air in suitable drain holes.

A climate that is always comfortable even in hot and cold climates, with thermal break windows

As we have seen, the first step to optimize light and home heating is to go for thermal break windows, to avoid heat loss and maintain comfortable the home climate.

On the other hand, combining a thermal break fixture with a selective low-emission glass with argon gas is the second step to allow the supply of luminous radiation protecting against UV rays, thus avoiding heat dispersion towards the outside.

So which of our thermal break windows would be more suitable whether you are in the mountains or in Dubai?

Among the various alternatives, our top of the range for thermal break aluminum frames is TRIAL VAL PLUS, with excellent insulating performance thanks to the triple 46mm glass.

Whether you prefer the warm effect of wood, the window for you is TRIAL PLUS, in wood aluminum.

For super-cold climates and passive house projects we recommend opting for quality PVC windows, like our ISOL PLUS model.